Business Introduction

Cheongwoo is a leading company that creates the myth of the steel structure field based on Korea's largest CG composite beam production facilityand

the best technology with management principle spearheading changing trends.

the best technology with management principle spearheading changing trends.

Business Overview

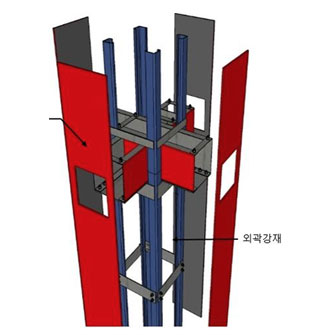

Until now, the method of construction has been carried out in a labor-intensive manner, such as installing formwork for steel frame assembly and concrete pouring in the site. However, in addition to the labor shortage in the field, such as the aging of skilled technicians and the reduction in youth inflow, the introduction of new methods to compensate for these shortcomings was inevitable due to the weakness of the safety, climate and other external environmental constraints.

Cheongwoo’s CG method is evaluated by the consumer as a groundbreaking construction method that compensates for the shortcomings of the existing method and is mass-produced in the factory and assembled at the construction site, reducing construction time and costs ensuring seismic resistance, fire resistance and safety.

Cheongwoo’s CG method is evaluated by the consumer as a groundbreaking construction method that compensates for the shortcomings of the existing method and is mass-produced in the factory and assembled at the construction site, reducing construction time and costs ensuring seismic resistance, fire resistance and safety.

Promotion Plan

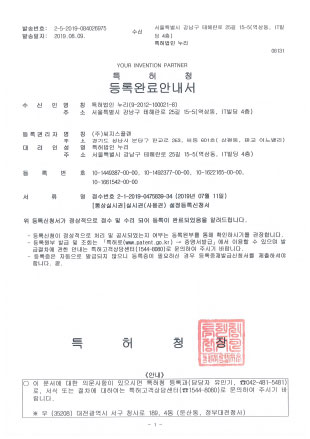

Based on four patents of CG Method, Cheongwoo expanded its Sacheon factory by 119,975㎡ in 2019 with a sales growth of more than 35% per year, starting with the 19,323 ㎡ Haman factory in 2013 in line with rapidly changing architectural trends. With 254 kinds of machinery such as laser cutters on a large site of 139,298㎡, we are ready to meet the growing demand and continue to grow to make the leap to midsize business with sales of KRW 162.7 billion in 2025.

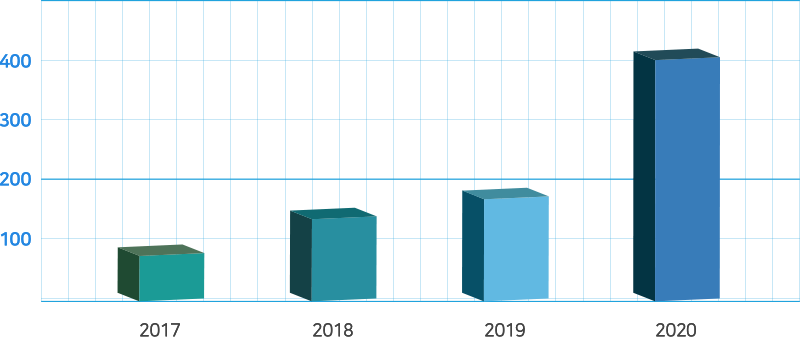

Operating Result

Recent Sales Record (in Million KRW)

| 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|

| 6,895 | 16,476 | 19,014 | 41,200 |